- Your cart is empty Browse Shop

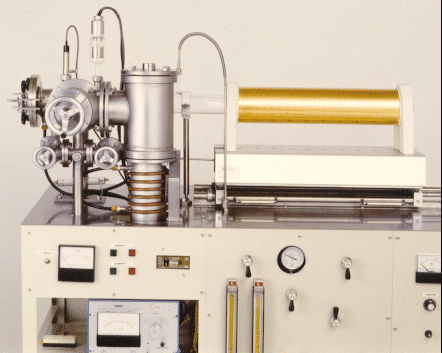

TransTemp Transparent Tube Furnace

The Lincoln Laboratory on the MIT campus is where the TransTemp transparent tube furnace was first created. In contrast to traditional furnaces, the TransTemp turns transparent at about 600°C, allowing one to observe a process as it happens within the furnace. A gold mirror is used in TransTemp transparent furnaces to reflect infrared radiation and serve as an insulator. Because simply a gold mirror is used as insulation, bulk is reduced and very quick rates of heating and cooling are possible. The TransTemp tube furnace should only be operated at a maximum temperature of 1000°C.

Construction :

Three coaxially placed tubes are used in the construction of TransTemp tube furnaces. Pyrex glass with a gold mirror on the inside makes up the outermost tube. Infrared light is heavily reflected by gold, which also serves as an insulator. Because gold is a poor reflector of visible light, it is also perfect for a transparent furnace. The gold mirror is shielded by the quartz shield found in the second tube. A resistive element is coaxially positioned inside the quartz shield. The element consists of many fixed coils that are brazed together. The element’s design will determine the precise temperature profile. The third tube, also known as the muffle or quartz tube, goes through the middle of the furnace and beyond its ends.

Tempreture Uniformity :

Only the center third of the heated length typically experiences a consistent temperature in traditional tube furnaces with packed or porous insulation. Due to heat loss at the ends, the temperature drops dramatically outside of this area. The heat is distributed uniformly down the length of the tube in the TransTemp tube furnace by the homogeneous reflection of infrared light. The mirror has uniform radial heat loss because it is uniform. The TransTemp tube furnace will maintain a constant temperature for 60% of its length when the ends are sealed.