-

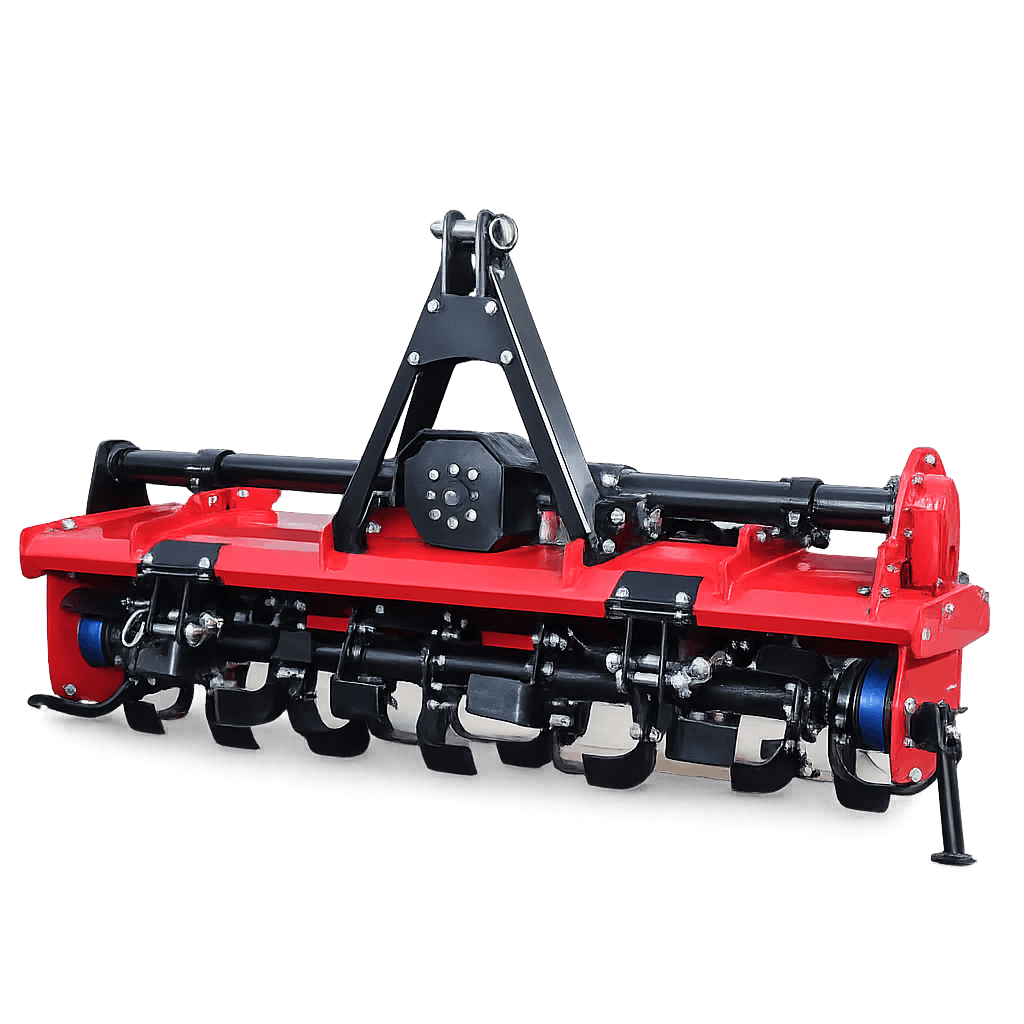

Agriculture

Implements

Overview

Splash brings a burst of energy and creativity, infusing life with bold and vibrant expressions. it’s a splash of color, an idea.

-

Tractor, bus

Seat

Overview

Cream represents a perfect blend of warmth and subtlety, offering a soothing and timeless appeal. Its versatile tone calmness.

-

Precision

Seat Mechanisms

Overview

Seat mechanisms engineered for smooth adjustment, long-lasting durability, and reliable performance

-

Engineering

Strong Foundations

Overview

We delivers reliable, high-quality infrastructure solutions with a focus on engineering excellence, timely execution,

-

Strong Presence

Across India

Overview

SAL Automotive serves customers across India with consistency, quality, and reliability.

Facility powered by experienced engineers and dedicated shop-floor experts.

Where Engineering Meets Reliability

Established in 1974, SAL Automotive Limited CIN:L45202PB1974PLC003516) (Formerly Swaraj Automotives Limited) is an emerging global manufacturer of Automotive Components, Seats and Agricultural Implements. SAL is a leading and preferred Supplier to the Indian Automotive Industry.

Inaugurated by the the Hon’ble President of India as Punjab Scooters Limited and started manufacturing scooter named as “Vijay Kesari”. Company diversified into manufacturing of Seats in 1986 and Seat Mechanism in 1994 in technological tie-up with Fuji Kiko of Japan. In the year 2014, company extended its product portfolio with agricultural implements.

Power & Precision

Trusted Through Innovation & Quality

Manufacturing excellence, under one roof.

Testing & Quality Facilities

- Profile Projector (PC Controlled)

- Rockwell & Vickers Hardness Testing

- Micro Hardness Tester

- Tensile Testing Machine

- PU Hardness Testing

- Salt Spray Test

- Environmental Testing (Hot/Cold)

- Dust Resistance Testing

Research & Design Engineering

- 2D/3D CAD Creation using AutoCAD/ Solid works

Bill of Material & Costing

Prototyping & Trials

Product Validation / Testing

Process Design

Design Calculations

Tolerance Stack up

Reverse Engineering

VA/VE , CRE

APQP (PPAP, DFMEA , PFMEA, CP etc.)

In-House Manufacturing Facilities

- Powder Coating

PU Line

Assembly Capacity: 3.2 lakh assemblies/month

CNC Pipe Bending

Laser & Plasma Cutting

VMC Machines

Fine Blanking Presses

Robotic Welding

Projection Welding

Mig Welding

Mechanical & Hyd Presses (Multiple Tonnage)

Heat Treatment

Traub & Header

Manufacturing Excellence

Our Activities

Awards And Recognition

Committed to transparency, sustainable growth, and .long-term value creation

Quarterly Results

- Financial Year 2025-2026

- Q1 Result

- Q2 Result

OUR CUSTOMERS